Humans have known about electricity for thousands of years, going back to the so-called Baghdad battery. Despite harnessing electricity in a useful way for the past 250 years, most people still don’t know how or why it works on a basic level.

Humans have known about electricity for thousands of years, going back to the so-called Baghdad battery. Despite harnessing electricity in a useful way for the past 250 years, most people still don’t know how or why it works on a basic level.

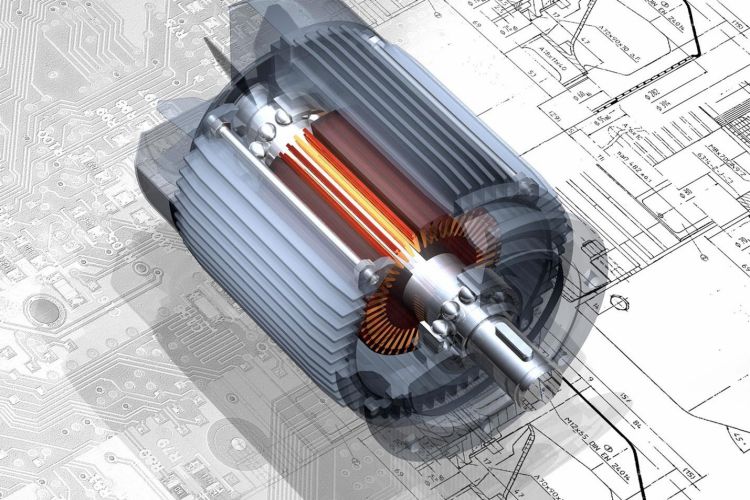

One of the most confusing parts of electrical usage is in electric motors. Do you want to know about the parts of an electric motor to know which is better for your applications?

Keep reading to find out what goes into electric motors, and a little about the power that drives them.

The Parts of an Electric Motor: AC/DC?

There are two general types of electricity, which means that you can have two general types of electric motors. Those are AC and DC. The parts of a DC motor are similar to the parts of an AC motor, with a few notable exceptions and where the electricity is allowed to flow.

DC electricity is the main electrical source of batteries and solar power systems. AC electricity is generated at most power plants, through turbines. A turbine is basically an electric motor in reverse, much like the alternator on your car.

What makes AC motors desirable in many cases is a quiet, high-speed, low-torque operation. DC motors, on the other hand, produce higher torque. Those differences in construction and application mean that we need to have a detailed electric motor parts breakdown.

The Parts of an AC Electric Motor

AC electric motors have fewer moving parts. In fact, only the rotor spins, and the rotor is positioned by a bearing. This means that AC motors are fairly simple to do maintenance and repairs on.

The basic parts of an AC electric motor are:

- The stators

- The rotor

- Fan and fan cover

- Rotor bearing

- Frame

The fan and fan cover fits over the end of the frame and pulls air through the AC motor as it operates. It generates quite a lot of heat, and as air is pulled through the motor, it exits the back of the AC electric motor.

The stators are stationary around the rotor. They have field windings in various configurations or various types of AC motors. Because of the nature of AC electric motors, they also speed variables by modifying the frequency of the current.

The Parts of a DC Electric Motor

DC electric motors have a high amount of torque, although they often have many moving parts. Before we get into the operation of the DC electric motor, we need to find out what goes into it.

- Armature

- Stator

- Bearings

- Brush

- Commutator

The armature is the rotating part of the DC electric motor and surrounds the spinning shaft that transmits kinetic force. A spring-loaded brush has electricity flow through it, which energizes the armature around the shaft.

In the AC motor, the windings were the stators, and the AC rotor had permanent magnets on it. In DC electric motors, both have their own windings. This is because DC electric motors generally work on the force of repulsion of like polarities, where AC uses the attraction of dissimilar polarities.

In simple terms, the DC electric motor is using a pushing force, while AC electric motors use a pulling force.

Know more about Specialized electrical motor repair.

Making DC Work Through Commutators

The commutator in DC motors changes in its electrical polarity as it passes along the stators. Stators in any electric motor are stationary part that usually holds a permanent or electromagnet.

Brushes and commutators wear out the fastest because of the friction and heat that builds up as they operate. For high-speed operation, DC electric motors are not the best option — unless you also need torque.

Commutators help to increase torque and give DC electric motors the essential power to lift elevators, move vehicles, and start combustible engines (the starter motor in your car).

In fact, the commutator is the main component that a DC motor uses to make DC electricity. DC electricity flows in only one direction, and the more segments you have to your commutator, the smoother the DC current’s peak power.

Braking an Electric Motor

Bearings on these shafts are designed to give high stability at the lowest friction possible. Since there’s a rather small amount of friction once you turn off the current flow to electric motors, a problem immediately comes up. You can’t have electric motor shafts spinning forever.

The biggest issue with this problem is that in almost every application, it’s unsafe, inaccurate, and takes a long time to stop spinning.

Enter the electric motor brake. There are two kinds of electric motor brakes, the spring set, and the electrically set brakes. Depending on what they’re used for, one is better suited to your application than the other.

For example, if you need a fail-safe brake, a spring-set electric motor brake is best. This would be well-suited to an elevator, for example. Spring set brakes use an electric, hydraulic, or pneumatic force to overcome the strength of springs that put friction torque against the movement of the generator shaft.

Electrically set brakes work in the opposite way. They only apply brake torque only when electricity is present. Usually, these brakes use a magnetic coil to actuate.

Three-phase and DC brakes are two forms of electric motor brakes commonly used on DC electric motors.

Understanding the Parts of an Electric Motor

Now that you understand the parts of an electric motor and what their purpose is, you should be able to determine the types of motor pretty quickly, along with the motor parts list you might need. You should also be able to understand the design intent for using an AC or DC electric motor in a given situation.

You even got to learn how to slow or stop an electric motor through the use of electric motor braking. Ready to learn more? Keep browsing our articles to learn more fundamentals and advanced knowledge on motors, electricity, power generation, and more!